| Availability: | |

|---|---|

| Quantity: | |

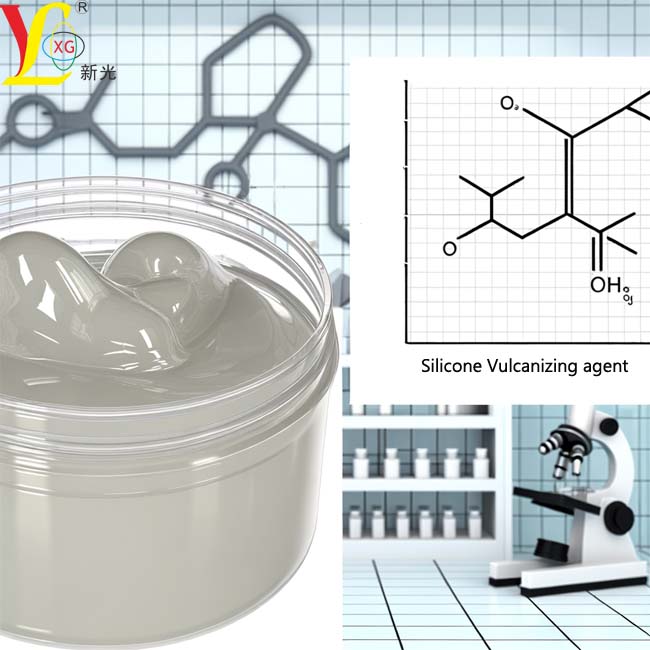

Silicone vulcanizing agent is a special auxiliary material used in the production of silicone products, which is mainly used to promote the vulcanization process of silicone, so that the silicone from the liquid state to the solid state, so as to obtain the required physical and chemical properties. It is particularly important in the printing industry as it provides excellent curing and fast production efficiency for silicone printing.

Effects on products

A. It is characterized by fast vulcanization, which greatly shortens the production cycle and improves the production efficiency.

B. Adhesion is significantly enhanced to ensure that the printed pattern is not easy to come off.

C.Showing excellent tensile and tear resistance, enhancing the durability and reliability of the product.

D. Meets the requirements of environmental protection, with no release of harmful substances, safeguarding the safety of users and the environment.

![]()

FAQ

Q1: What is the operating temperature of silicone vulcanizing agent?

A1: Usually between room temperature and 150℃, the specific temperature should depend on the product requirements and the type of vulcanizing agent.

Q2: What is the amount of vulcanizing agent to be added?

A2: Usually according to the type of silicone and the required vulcanization time, it is recommended to follow the product manual or the guidance of technicians.

Q3:What do we need to pay attention to during the vulcanization process?

A3:During the vulcanization process, it should be ensured that the vulcanization environment is clean and dust-free to avoid impurities affecting the silicone. At the same time, vulcanization time and temperature should be strictly controlled to ensure the vulcanization effect.

Q4:How to keep it?

A4:After vulcanization, the silicone products should be stored in a dry, cool and ventilated place, avoiding direct sunlight and high temperature to ensure the stability and life of the products.